.

Metallurgical Engineering

- Develop rational approaches to structural integrity.

- Develop detailing for dynamically-loaded structures.

- Apply fitness-for-service analysis to determine least-cost, safe disposition of cracks and damage.

- Specify materials based on properties, corrosion, fabricability and cost.

- Develop custom specifications that ensure design properties at lowest overall cost.

Welding Engineering

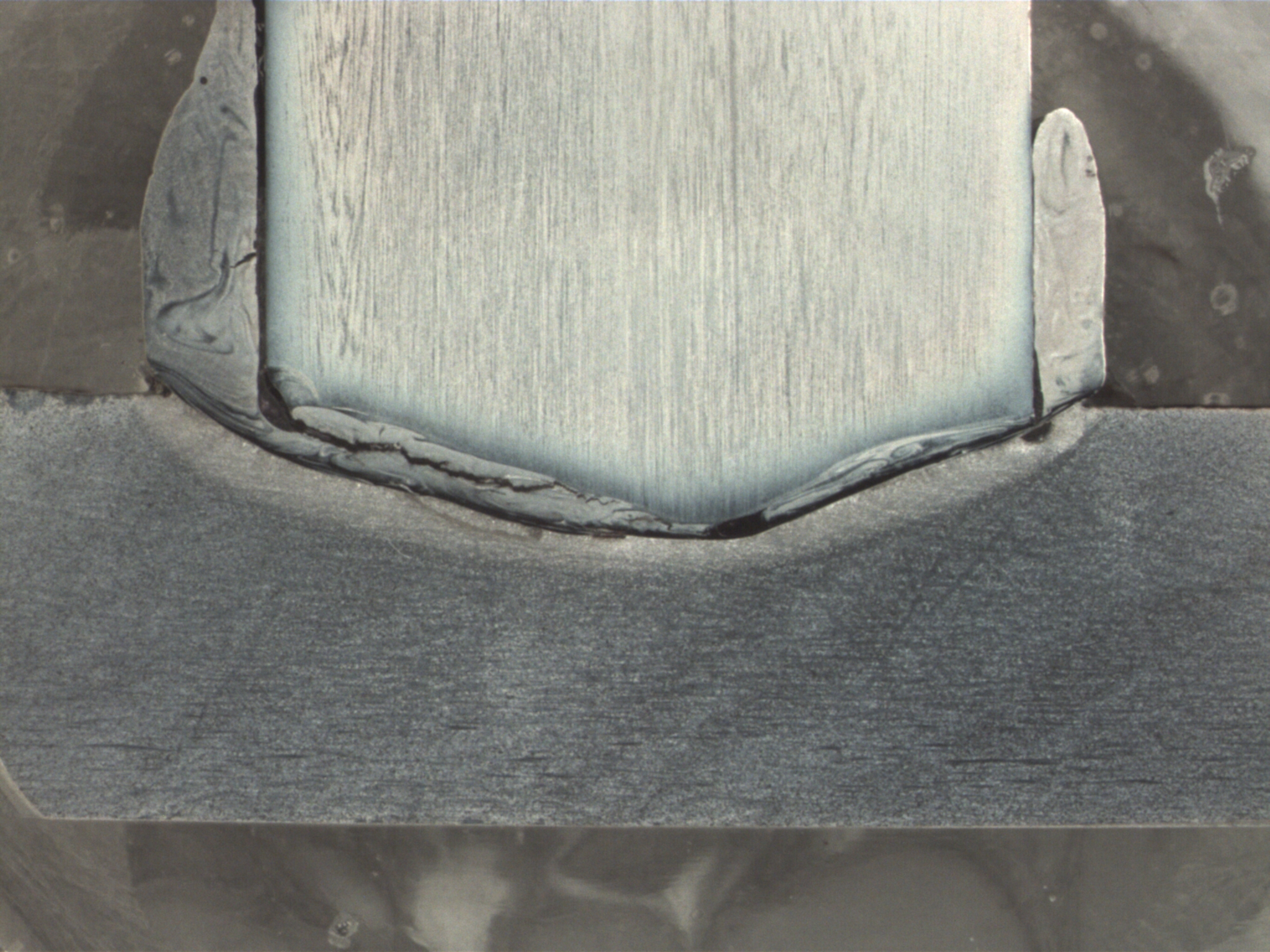

- Develop and review welding procedures to ensure design properties and conformance to code.

- Define inspection strategies, and specify construction and in-service examinations.

- Develop optimum fabrication strategies while anticipating and solving fabrication problems early.

- Develop optimum repair strategies.

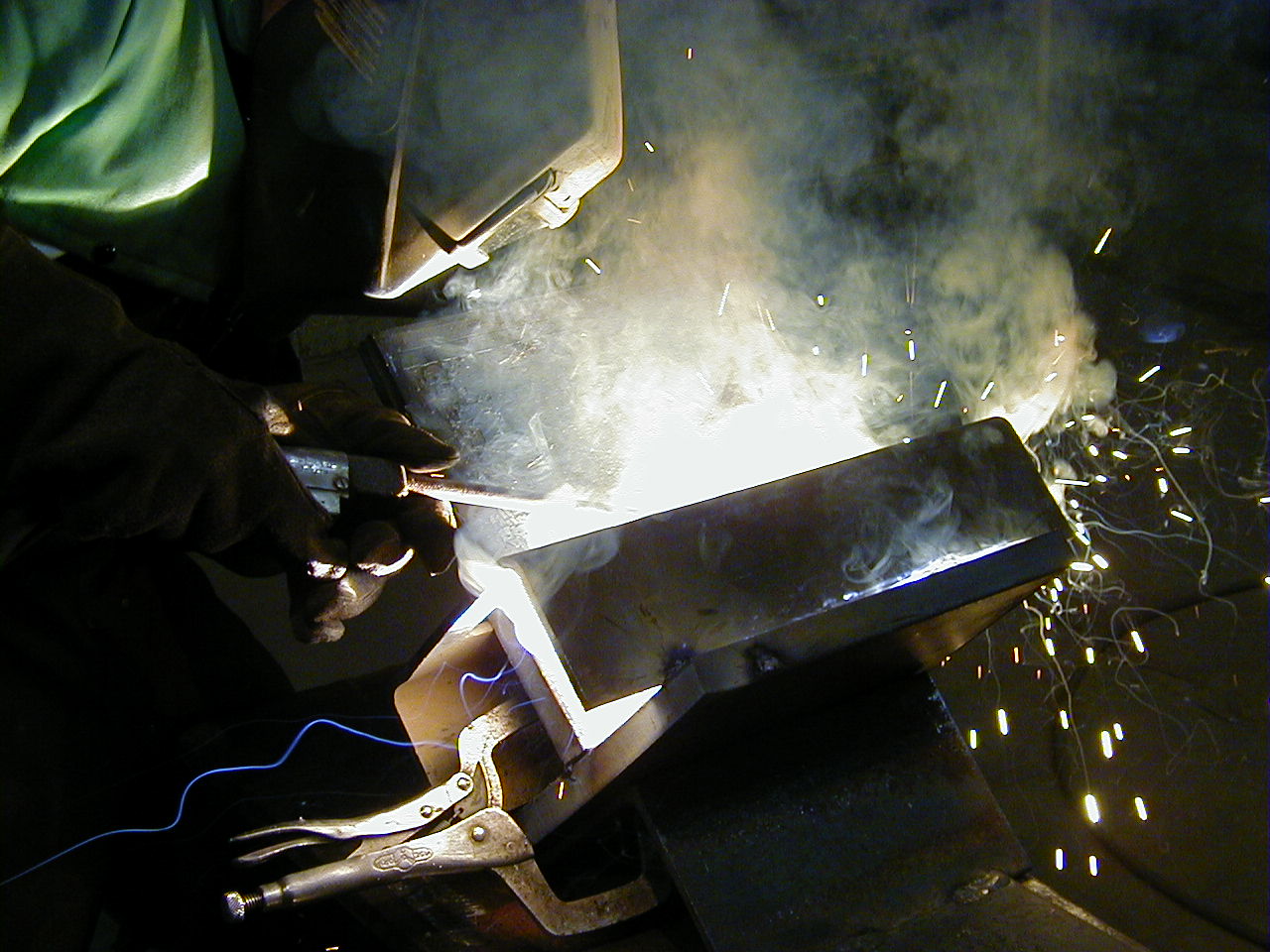

- Supervise critical welding and repairs.

Technical Training

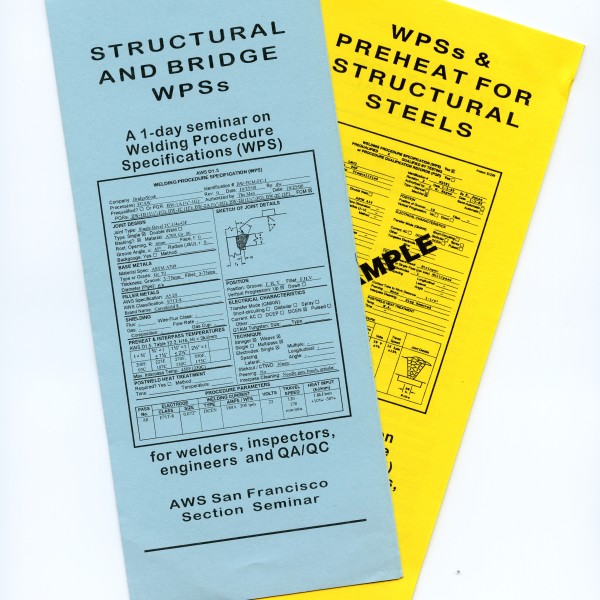

- Certified Welding Inspector (CWI) Training (including welding technology, hands-on & code)

- In-house training on steel construction technology (e.g., steel, welding, & inspection technology, welding codes)

- Seminars developed from Client’s outlines (e.g, welding, inspection, codes, construction technology for engineers)

Forensic Engineering

- Site investigations of structural failures

- Metallurgical investigations of service damage and failures

- Expert Witness and Expert Consulting to attorneys